新质生产力引领:智能工厂全面兴起

China has built over 30,000 basic-level smart factories, 1,200 advanced-level and 230 excellence-level smart factories. This progress comes from a national training program to develop smarter manufacturing systems.

These excellence-level smart factories are located in all 31 provinces and cover more than 80% of major manufacturing industries. They have created about 2,000 advanced systems, including smart storage, online quality checks, digital (数字的) product design, and intelligent (智能的) production planning.

____▲____ These factories have reduced product development time by 28.4%, increased production efficiency by 22.3%, lowered defective products by 50.2%, and cut carbon emissions by 20.4% on average. Such improvements help companies save costs, produce higher-quality goods, and protect the environment.

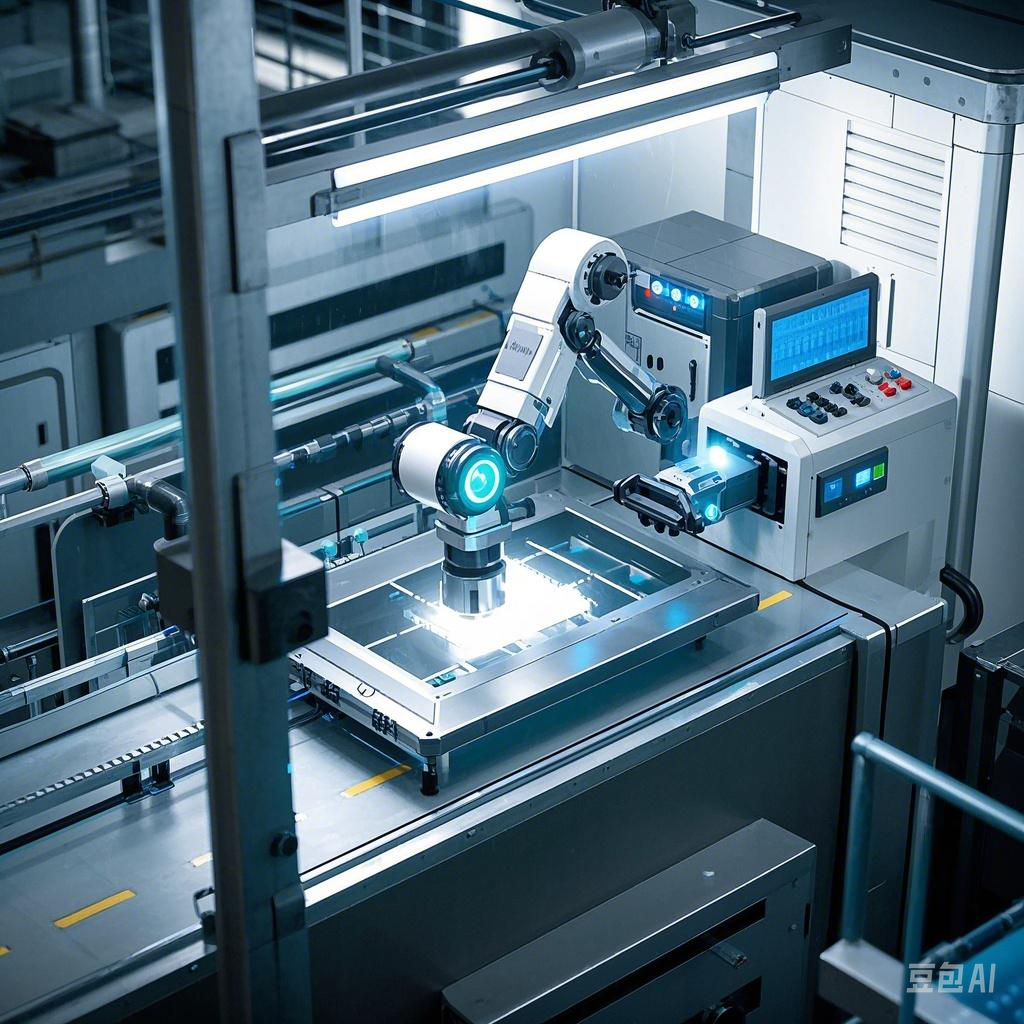

Smart factories use technology like AI and big data to automate tasks and make better decisions. For example, machines can now find out product flaws, and systems can track materials to reduce waste. These changes are transforming (改变) traditional factories into modern, eco-friendly workplaces.

China’s smart factory program shows how technology is improving manufacturing. Experts say this shift will make Chinese products more competitive globally while supporting sustainable development. This is an important step towards a better future.